watchnerd

Grand Contributor

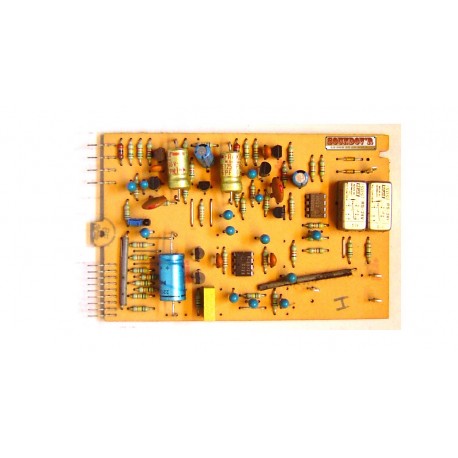

How necessary or beneficial is it to pre-emptively recap vintage electronics?

I understand the need to replace old failing or leaking capacitors.

But when I read about restorations of vintage electronics, they often to a 'full recap', replacing every original capacitor, regardless of whether the caps have problems or not.

Obviously, this can involve dozens, or even hundreds of new caps, with many hours of desoldering / soldering.

Is this really beneficial or necessary?

I understand the need to replace old failing or leaking capacitors.

But when I read about restorations of vintage electronics, they often to a 'full recap', replacing every original capacitor, regardless of whether the caps have problems or not.

Obviously, this can involve dozens, or even hundreds of new caps, with many hours of desoldering / soldering.

Is this really beneficial or necessary?