Very cool so far. Did you create the frame for the grille and 3D print it?

-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project Rectonics aka Kamu M1: Powered streaming speaker

- Thread starter KamuDesigns

- Start date

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #22

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #23

Yes! Everything but the sidepanels and electric parts are 3d printed.Very cool so far. Did you create the frame for the grille and 3D print it?

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #24

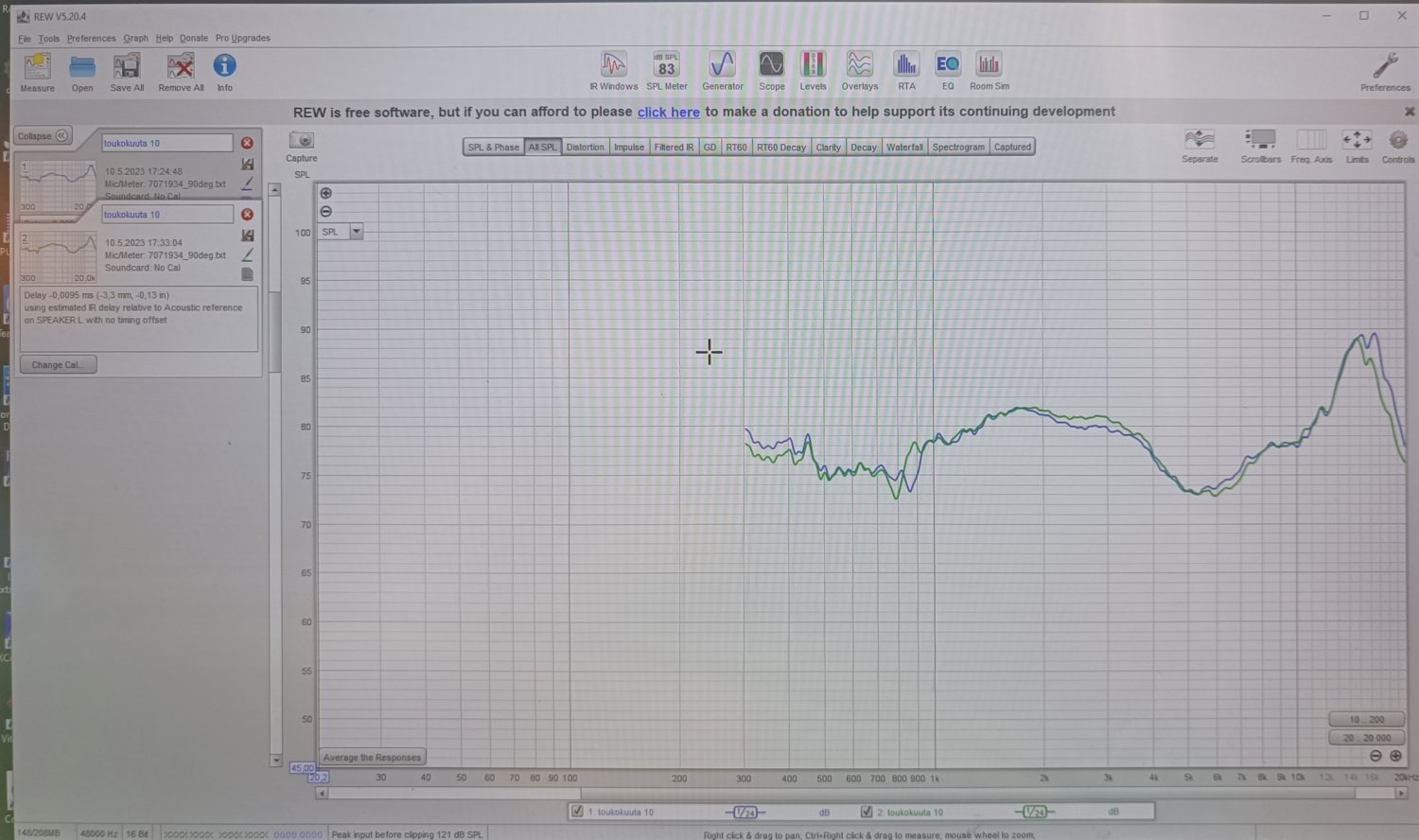

Tested the tuning today. It was a bit lower than expected. I was aiming for 47hz and end result was 40hz. Surely I can raise it a bit since the last portion of the resonator is separate, but I've could have gone with a bigger port if I knew that tuning is going to lower. Apparrently measuring port lenght at absolute centerline produces lower tuning than intended. Go figure

View attachment 1169524

Last edited:

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #25

I took 2 bmr drivers and measured them in a wg close range so don't pay much attention of the shape of the fr. The whole idea is to compare drivers.

Apparrently they are of a constant quality. Another one is broken in and another isn't. They still do measure inside 1db so I'm not going to go through the rest of the drivers.

Apparrently they are of a constant quality. Another one is broken in and another isn't. They still do measure inside 1db so I'm not going to go through the rest of the drivers.

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #26

I assembled the speakers today and attached the logos. Still working on the grilles, but I can dive into the amps dsp tomorrow and take some measurements.

badspeakerdesigner

Active Member

- Joined

- Jan 12, 2023

- Messages

- 274

- Likes

- 446

Looking very spiffy there. So close. Thing is like 99% there in terms of looking like a commercial product and that's impressive.

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #28

That 1%? Woofer screws?Looking very spiffy there. So close. Thing is like 99% there in terms of looking like a commercial product and that's impressive.

badspeakerdesigner

Active Member

- Joined

- Jan 12, 2023

- Messages

- 274

- Likes

- 446

That 1%? Woofer screws?

Well for me it's the very slight burrs (idk what to call them) where the wood joins the printed enclosure. I don't think the bolts are really a problem, but the woofers basket isn't the most aesthetically pleasing by itself. With a grill it won't matter and your grills looked really cool.

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #30

Round or chiseled? For the life of me I can not make up my mind...

badspeakerdesigner

Active Member

- Joined

- Jan 12, 2023

- Messages

- 274

- Likes

- 446

Round

jmf11

Member

Hello,

This is an brilliant result and innovative way to proceed. For the 3D printed part, which level of infill did you used? Do you consider that it is the right one, or would increase/lower it ?

Does it "rings" different from wood?

JMF

This is an brilliant result and innovative way to proceed. For the 3D printed part, which level of infill did you used? Do you consider that it is the right one, or would increase/lower it ?

Does it "rings" different from wood?

JMF

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #33

As far as stiffness goes it's quite the same as birch ply. I used 3 0.6mm walls and 35% grid infill. I could have gone a bit higher, but I absolutely wanted to keep the halves under 1kg. Cabinet structural resonances were still above woofers band @600-700hz so I'd call this a success.Hello,

This is an brilliant result and innovative way to proceed. For the 3D printed part, which level of infill did you used? Do you consider that it is the right one, or would increase/lower it ?

Does it "rings" different from wood?

JMF

jmf11

Member

Thanks a lot for this feedback. Your project demonstrates that 3D printing makes sense for speakers, with reasonnable infill. Working with halves solves prart of the issue related to the bed size. And printing on the side offers new possibilities.

Well done !

I imagine that it still represents very long prints...

JMF

Well done !

I imagine that it still represents very long prints...

JMF

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #35

You just need to upgrade your machine's flow and cooling capability so you can print with larger nozzles. These averaged around 27 hours per half so it's not too bad.Thanks a lot for this feedback. Your project demonstrates that 3D printing makes sense for speakers, with reasonnable infill. Working with halves solves prart of the issue related to the bed size. And printing on the side offers new possibilities.

Well done !

I imagine that it still represents very long prints...

JMF

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #36

Final design iteration of the grille, but I need better glue. I used spray contact cement, but that seems to have tendency to loosen up when heat is applied. I tried with a hairdryer and sure enough the glue gave out.

Since I absolutely need a glue that actually hardens, I'm going try to get my hands on some spray ca and spray accelerator.

Maybe with that I dare to try with the brown fabric.

Since I absolutely need a glue that actually hardens, I'm going try to get my hands on some spray ca and spray accelerator.

Maybe with that I dare to try with the brown fabric.

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #38

They are also printed. The fabric is glued from the front side just from the lowest point around the 'dustcap' and from the backside.Nice looking speaker!

Did I miss how you made those grills? Or just purchased (source)?

Front side is glued with spray adhesive and ca in the back.

It stays in place with the aid of neodiym magnets.

Attachments

Hi @KamuDesigns , amazing project! I got my first 3D prints done a couple of weeks ago and learning on the go.

For electronics enclosures i am using PETG because I am afraid that PLA starts to soft if electronics get a bit hot and don't have a dedicated area to print ABS. But I am not finding PETG so easy to print, and worse than that, i am seeing that the dimensional stability is not great. Well, they are thermoplastic s after all. I wonder if it is worth the risk of sticking to PLA.

Seeing you have amps in there, wanted to ask you what sort of filament are you using and what is your experience being so far?

Thanks a lot!

For electronics enclosures i am using PETG because I am afraid that PLA starts to soft if electronics get a bit hot and don't have a dedicated area to print ABS. But I am not finding PETG so easy to print, and worse than that, i am seeing that the dimensional stability is not great. Well, they are thermoplastic s after all. I wonder if it is worth the risk of sticking to PLA.

Seeing you have amps in there, wanted to ask you what sort of filament are you using and what is your experience being so far?

Thanks a lot!

OP

KamuDesigns

Member

- Joined

- Dec 18, 2022

- Messages

- 33

- Likes

- 53

- Thread Starter

- #40

This filament is matte high temperature pla that I got from anycubic surprise box. High temperature means that it's designed to withstand annealing, which is process I did not use so it's basically just matte pla+ that prints great.Hi @KamuDesigns , amazing project! I got my first 3D prints done a couple of weeks ago and learning on the go.

For electronics enclosures i am using PETG because I am afraid that PLA starts to soft if electronics get a bit hot and don't have a dedicated area to print ABS. But I am not finding PETG so easy to print, and worse than that, i am seeing that the dimensional stability is not great. Well, they are thermoplastic s after all. I wonder if it is worth the risk of sticking to PLA.

Seeing you have amps in there, wanted to ask you what sort of filament are you using and what is your experience being so far?

Thanks a lot!

What comes to temperature resistance you'd need the whole enclosure mass to be at least at 65c before it would be at glass transitional temperature. Obviously you would't use pla in sauna speakers or use those speaker in arizona garden party during summer. Otherwise it's not likely that any part of speaker reaches temperatures hot enough for it to turn soft.

Petg in turn isn't stiff enough for enclosures imo. You would have to use cf filled petg to gain enough stiffness.

Maybe a small travel speaker could do with plain petg... I have to try that to say for sure.

Also you'd need enclosed printers with at least 50c internal temperature for petg, abs, asa and other higher temperature filaments.

If you are printing smaller stuff like waveguides then you can just use draft/ooze shield to trap the heat and prevent warping.

Similar threads

- Replies

- 27

- Views

- 3K

- Replies

- 9

- Views

- 995