Yes I pointed them out in a previous post. Smps will have them for emi reduction. There will be leakage currents. Hence if you don't have the speaker low connected to measurement system screen they will end up in the measurement signal low wire and input amp.I figured you've experimented to find the best wiring topology from an induced noise perspective. So there's no X2 rated caps/varistors etc from the SMPS primary filters to chassis via mounting screws anywhere as is often done with a lot of gear?

-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

- Forums

- Audio, Audio, Audio!

- Amplifiers, Phono preamp, and Analog Audio Review

- Stereo and Multichannel Amplifier Reviews

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

March Audio P502 Stereo Amplifier Measurements

- Thread starter amirm

- Start date

restorer-john

Grand Contributor

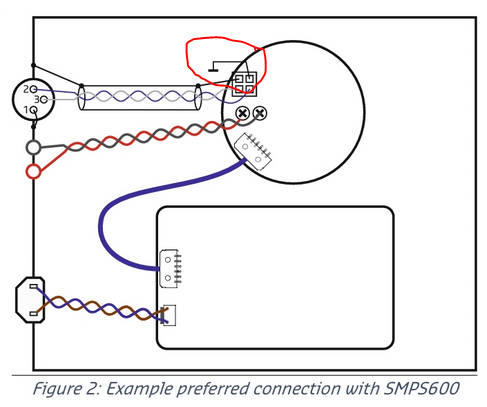

So the chassis earth circled in red is what, a PSU OV tap point or something else?

Is the SMPS600 or equivalent supply connected to the chassis at any point in addition?

Is the SMPS600 or equivalent supply connected to the chassis at any point in addition?

No, that's actually a power trigger input specifically for the NC400. To 0 volts triggers the amp on. Not relevant for this amp. I just used the diagram as it's to hand. The Nc252 is an integrated psu and amp board.

Speaker neg is ground referenced and therefore connected to input signal screen on the board. The smps caps connect to the heatsink plate through a mounting pillar shown in that previous post. This is obviously bolted to chassis.

Speaker neg is ground referenced and therefore connected to input signal screen on the board. The smps caps connect to the heatsink plate through a mounting pillar shown in that previous post. This is obviously bolted to chassis.

Last edited:

restorer-john

Grand Contributor

It seems like you're all over it.

When you work on vintage metal gear like I do, the various earthing/grounding/shielding schemes on SE (RCA) stuff vary from logical to insanity with plenty of the practices clearly being patches to tame noise. Sometimes there are 50 or more chassis connections, some through switches, pot shafts, tuner knobs, antenna jacks, multiple connections from screws in RCA jack mounts, PCB mount points, combinations of star and PSU return etc.

When you work on vintage metal gear like I do, the various earthing/grounding/shielding schemes on SE (RCA) stuff vary from logical to insanity with plenty of the practices clearly being patches to tame noise. Sometimes there are 50 or more chassis connections, some through switches, pot shafts, tuner knobs, antenna jacks, multiple connections from screws in RCA jack mounts, PCB mount points, combinations of star and PSU return etc.

Kudos to @March Audio on his responses to questions and suggestions in this thread. That level of transparency and good will is not very common I think...

Makes me conclude that I've found a good supplier of new amps whenever I am ready to make a change.

Makes me conclude that I've found a good supplier of new amps whenever I am ready to make a change.

The P502 I had for 2 weeks ran hot. By that I mean not too hot to touch but only just. The Bel Canto mono-blocks it was bought to replace run barely warm. I returned it for that reason.

Driving what speakers and to what levels? The REF600M from Bel-Canto?

Curious - Don

I ran that unit here after you retuned it and while it was warmer than the smaller p122 it never became ‘hot’ you could easily keep your hand on it for eternity should you wish.The P502 I had for 2 weeks ran hot. By that I mean not too hot to touch but only just. The Bel Canto mono-blocks it was bought to replace run barely warm. I returned it for that reason.

Keith

Marou

Member

- Joined

- Oct 2, 2018

- Messages

- 8

- Likes

- 7

Bel Canto eOne 300m into Harbeth P3ESRs at the levels my wife permits.Driving what speakers and to what levels? The REF600M from Bel-Canto?

Curious - Don

The P502 I had for 2 weeks ran hot. By that I mean not too hot to touch but only just. The Bel Canto mono-blocks it was bought to replace run barely warm. I returned it for that reason.

We check all units for temperature as part of testing (playing music at good level and plugged into real speakers) and Keith's unit was normal at 38 deg C after a long soak.

Keith and I spoke about the specific unit and his tests couldn't find any problem, it ran at normal temperature.

P502 38 deg c

P252 32 deg c

P122 28 deg c

BTW the Bel Cantos are comparable to the P252 in terms of power, so its not comparing like with like.

Last edited:

If I read rightly the P502 is a much more powerful amplifier so makes sense it would run a little warmer even in class D. That said I wonder if something else was going on...

If I read rightly the P502 is a much more powerful amplifier so makes sense it would run a little warmer even in class D. That said I wonder if something else was going on...

P502 is 500 watts rms per channel 4 ohms,

P252 is 250 watts

P122 is 125 watts

The idle losses as you indicate do increase with the more powerful units. Keith has tested it and can't get it to do anything unusual, so we can't draw any further conclusions.

So 10 degC warmer for the higher-power unit, but that's still only 1 degC above normal body temperature. Seems like something else might be at play, perhaps inadequate ventilation, or something? I found how hot something had to be to be too hot to touch at one point and posted it here but would have to dig again. Senility...

I agree. Ventilation is important for the P502. It shouldn't be placed on other warm equipment or have the vent slots blocked such as putting it on a carpet or too close to cabinet/ other equipment sides. Its a kW in a shoebox and Amir got it bursting to over 650 watts per channel!So 10 degC warmer for the higher-power unit, but that's still only 1 degC above normal body temperature. Seems like something else might be at play, perhaps inadequate ventilation, or something? I found how hot something had to be to be too hot to touch at one point and posted it here but would have to dig again. Senility...

We haven't had any specific issues with temp, but the cooler the better. As such we are going to fit taller feet to the amps to assist. Also the next batch will have longer vent slots.

I would estimate 50 deg C to be getting too hot to comfortably touch. BTW we measured our typical amp temps at 24 deg C ambient.

Last edited:

I agree. Ventilation is important for the P502. It shouldn't be placed on other warm equipment or have the vent slots blocked such as putting it on a carpet or too close to cabinet/ other equipment sides. Its a kW in a shoebox and Amir got it bursting to over 650 watts per channel!

We haven't had any specific issues with temp, but the cooler the better. As such we are going to fit taller feet to the amps to assist. Also the next batch will have longer vent slots.

I would estimate 50 deg C to be getting too hot to comfortably touch. BTW we measured our typical amp temps at 24 deg C ambient.

120 degF, 48 degC is the hottest recommended for hot water, requiring about 5 minutes before severe skin burning.

140 degF, 60 degC, will burn in about 5 seconds.

Seems like you are spot-on!

References:

ASTM C1055 (Standard Guide for Heated System Surface Conditions that Produce Contact Burn Injuries) recommends that pipe surface temperatures remain at or below 140°F. The reason for this is that the average person can touch a 140°F surface for up to five seconds without sustaining irreversible burn damage.

The most common regulatory standard for the maximum temperature of water delivered by residential water heaters to the tap is 120 degrees Fahrenheit/48 degrees Celsius. At this temperature, the skin of adults requires an average of five minutes of exposure for a full thickness burn to occur.

Tks

Major Contributor

- Joined

- Apr 1, 2019

- Messages

- 3,221

- Likes

- 5,496

I don't get why people are a bit off put about a amp that's a bit warm. That's actually good, it means the transfer of heat is operating properly. Now if it's scolding hot, then that may be perhaps an instance where the thermal solution is inadequate, and active cooling, or at the very least, passive heatsinks should exist. My favorite? A case design that makes contact with heat producing parts that is a part of the case itself is the best if you're going the passive route. Top vents are most ideal if there are going to be any vents if performance is concerned, though negligible if side vents exist at a similar height to the top panel, and it prevents from dust setting in the amp. That's one thing I hate about top vents like on my 789, just dust always falling in there. Bottom vents are meh, especially as the height of a case grows.

At any rate, the most important portion of all these temperature concerns, is looking up the specification sheets of the parts and their operational temperature limits. If they fall under such a degree, then all is well (though that would require thermal imaging of all the parts during operation with thermal probes). Besides this, I think all parts that produce localized heat should have some sort of thermal dissipation aided by heatsinks in some fashion. It's not an all emcompassing rule, but safe to say heat and power cycles are the death of many electronics (or at least exacerbated by it in theory at least)

At any rate, the most important portion of all these temperature concerns, is looking up the specification sheets of the parts and their operational temperature limits. If they fall under such a degree, then all is well (though that would require thermal imaging of all the parts during operation with thermal probes). Besides this, I think all parts that produce localized heat should have some sort of thermal dissipation aided by heatsinks in some fashion. It's not an all emcompassing rule, but safe to say heat and power cycles are the death of many electronics (or at least exacerbated by it in theory at least)

Yes if you got a large box with poor thermal coupling , the outside may not get so hot ...

hindsight

Kudos to @March Audio on his responses to questions and suggestions in this thread. That level of transparency and good will is not very common I think...

Makes me conclude that I've found a good supplier of new amps whenever I am ready to make a change.

Me too!

Marou

Member

- Joined

- Oct 2, 2018

- Messages

- 8

- Likes

- 7

You haven’t had any ‘specific issues with temp’ but a customer has returned a unit because it runs hot and in future you’re going to fit taller feet and longer vent slots to solve a problem you say doesn’t exist.I agree. Ventilation is important for the P502. It shouldn't be placed on other warm equipment or have the vent slots blocked such as putting it on a carpet or too close to cabinet/ other equipment sides. Its a kW in a shoebox and Amir got it bursting to over 650 watts per channel!

We haven't had any specific issues with temp, but the cooler the better. As such we are going to fit taller feet to the amps to assist. Also the next batch will have longer vent slots.

I would estimate 50 deg C to be getting too hot to comfortably touch. BTW we measured our typical amp temps at 24 deg C ambient.

Similar threads

- Poll

- Replies

- 145

- Views

- 23K

- Replies

- 351

- Views

- 69K

- Replies

- 897

- Views

- 122K

- Replies

- 57

- Views

- 11K

- Replies

- 72

- Views

- 12K