-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

- Forums

- Audio, Audio, Audio!

- DACs, Streamers, Servers, Players, Audio Interface

- Digital To Analog (DAC) Reviews and Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making a Case/Enclosure for the Khadas Tone Board

- Thread starter TimW

- Start date

maxxevv

Major Contributor

- Joined

- Apr 12, 2018

- Messages

- 1,872

- Likes

- 1,964

I see.No, just because I didn't like it too compact, but it's still only 11cm (4,33in)

At a glance , it sure looked a lot like the Atom's width at 127mm.

Veri

Master Contributor

- Joined

- Feb 6, 2018

- Messages

- 9,598

- Likes

- 12,040

Thank you TimW and others for this great guide. The templates and guide worked without issue. I had some scraps of walnut in the garage and decided to make a wooden face plate to class it up a little bit for desk use. I cut a piece of walnut roughly similar to the aluminum face plate although thicker and also wider as the screw holes were a little close to the edge for wood on the top side. I had some ideas about matching the contours and lines of the enclosure, routing the edges, and counter sinking the screws but ultimately decided for a clean look with proud screws and a single afternoon of shaping. The enclosure screws are thankfully more than long enough to fit the wooden face plate which is 1/4 inch thick. I finished the face plate using only sand paper, a file, and a drill for the holes. I sanded to 1000 grit and sealed it with 3 coats of Danish Oil for a natural look but this could be taken much further from a design and finish standpoint. I used the 5V pads outlined in the guide to wire up an aux LED. This is a generic ebay 3mm LED which fit perfectly in an 1/8 in. hole counter sunk from behind with a 1/4 in. bit so it just protrudes through the face. I used a 2k ohm resistor with an orange LED to give a faint glow that is not distracting facing me on the desk. I used hot glue to secure the LED and resistor to ensure nothing moves or shorts against the housing. Finally I used a 3M picture hanging strip to secure the DAC to the amp rather than rubber feet. That is pretty much it. Building this was a lot of fun and paired with JDS Atom amp, HD6xx phones I have a pretty slick looking and great sounding setup for under $500, can't be happier about that. Thanks for reading and hopefully this inspires someone else to give it a shot.

infinitesymphony

Major Contributor

- Joined

- Nov 21, 2018

- Messages

- 1,072

- Likes

- 1,809

Everyone's come up with some cool solutions for cases. Would any of you be willing to make a small run of them for the community?

As far as I can tell, right now our only pre-made options are the Audiophonics case from France (~$60 shipped to the US) and the Pillars case which seems to be MIA.

As far as I can tell, right now our only pre-made options are the Audiophonics case from France (~$60 shipped to the US) and the Pillars case which seems to be MIA.

Everyone's come up with some cool solutions for cases. Would any of you be willing to make a small run of them for the community?

Do you mean one in cnc?

infinitesymphony

Major Contributor

- Joined

- Nov 21, 2018

- Messages

- 1,072

- Likes

- 1,809

Honestly any kind of case, though my preference would be for something not 3D-printed unless it has a reasonable amount of heat resistance.

Silou

Active Member

- Joined

- Oct 5, 2018

- Messages

- 245

- Likes

- 114

Did you design the case youself and just sent them the cnc files or did they design it for you?If you like my model I can ask the price for a small batch (at least 5) and let you know, but certainly it will not be cheap, mine was 155 euro. Plus shipping from Italy

maxxevv

Major Contributor

- Joined

- Apr 12, 2018

- Messages

- 1,872

- Likes

- 1,964

And I thought mine was expensive ....If you like my model I can ask the price for a small batch (at least 5) and let you know, but certainly it will not be cheap, mine was 155 euro. Plus shipping from Italy

You forget the quote of my first version... double upAnd I thought mine was expensive ....

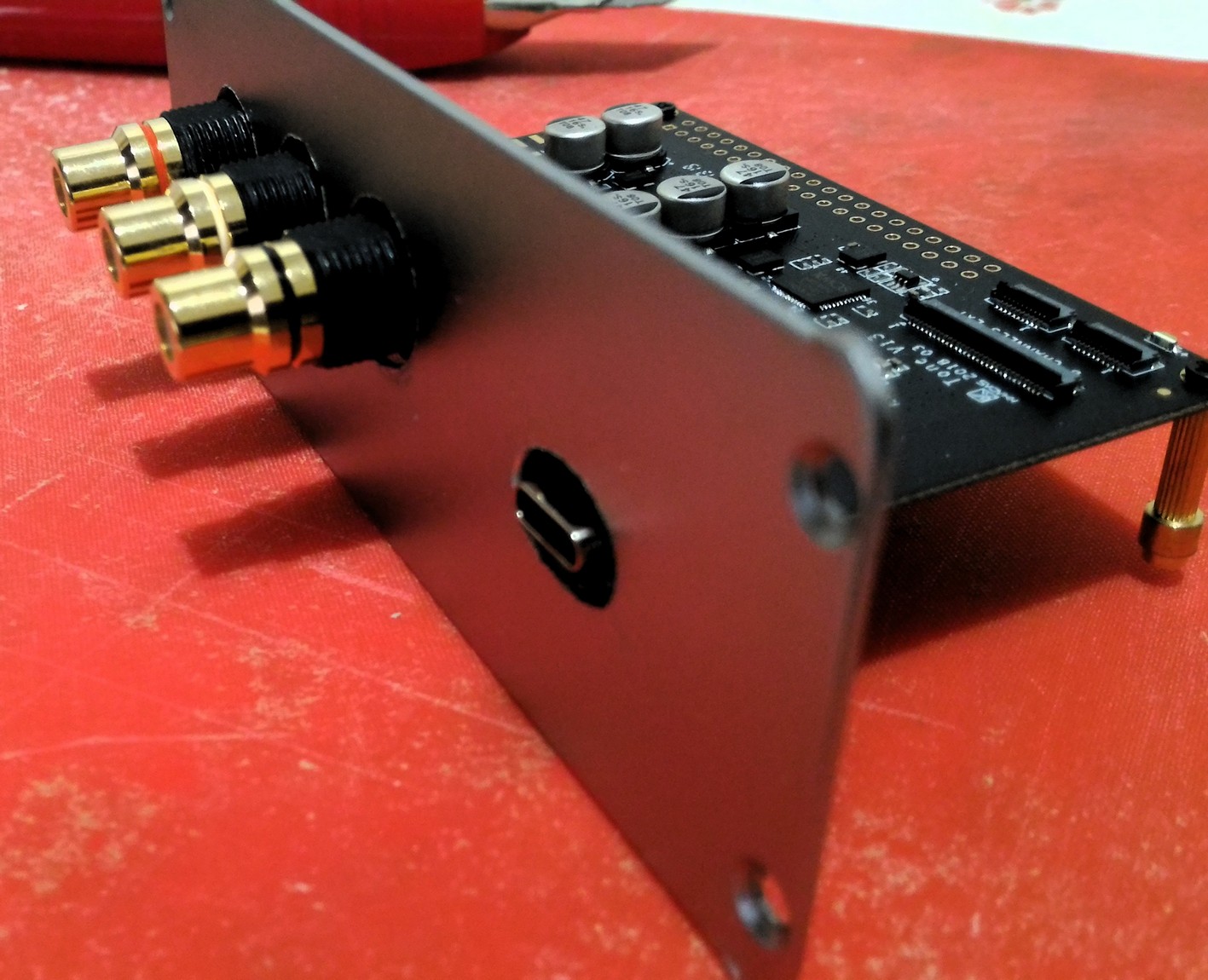

Hi everybody, my first post just to add my work for my new Tone Board:

I got a slightly oversized box cause it was only 7€ from ebay and wanted to see what I could get keeping all costs at the bare minumum.

I don't have a press drill and I'm not much experienced working metal with freehand drill, so the holes wer not really perfect but the plastic lockers of the tone board masked all the imperfections very well. As for the usb hole, it was really messed up at the beginning but I refined it wit my dremel and made it about elliptical. since it turned out a bit large i decided to seal it at the back with electrical tape that and just sliced it in the middle so that the usb port juste pushed itself through it keeping it as some kind of "glove", this ensured me against casual contact with the metal case:

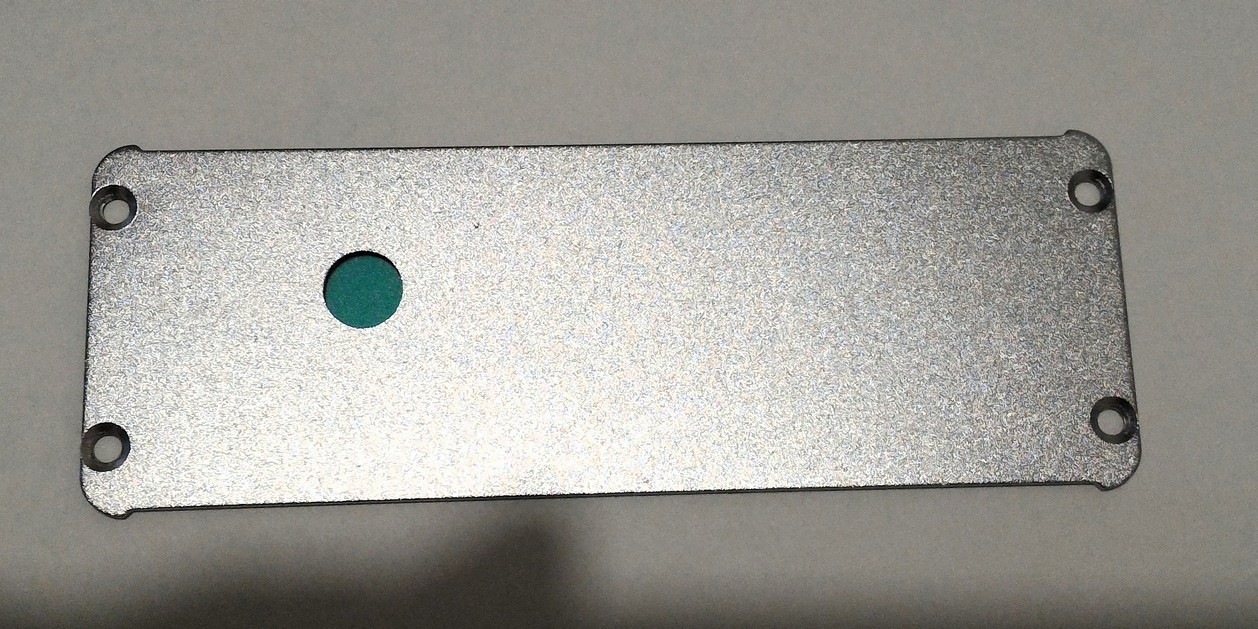

I didn't want a too much flashy led on the front and preferred to make use of the integrated led of the Tone Board, creating a small aperture on the front letting it pass through it. I used colored flashlight filter (5€ from amazon for 20 pieces) to close the hole, it helps diffusing the light and can be changed in seconds if you want another color. At the moment i used the green\blue:

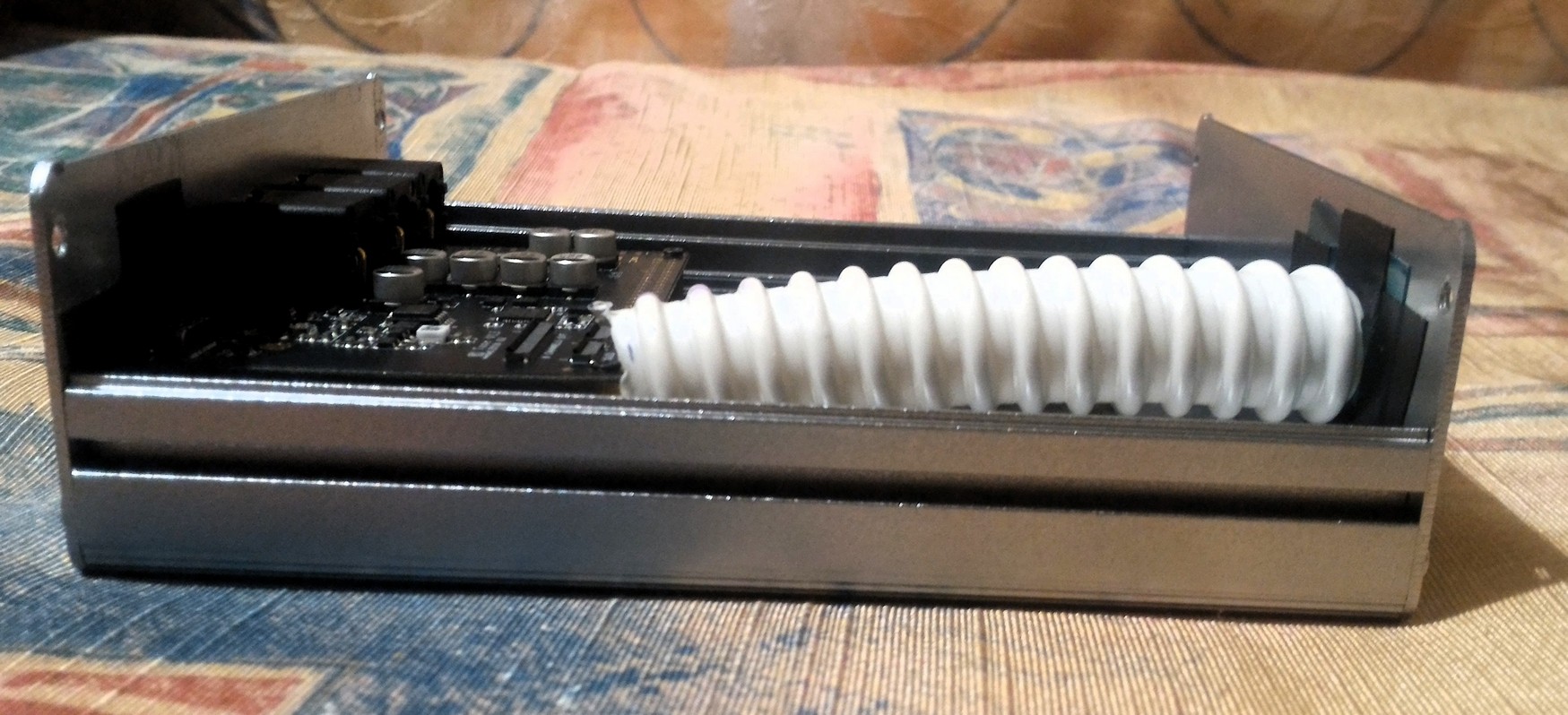

But since the led is slightly far from the front panel I made a sort of "tunnel" with a spare plastic corrugated pipe finely fitted, just to bring the light more directly to the hole:

It gave it a misteryous look so I can now trick fanatic audiophiles telling them this is the "black magic esoteric duct of good sound"

Finally, I placed on the bottom a leftover metal plate (covered with carbon-style vinyl just for fancy) to add some weight to the body and stuck a leftover rubber mat place on the upper part of the body to eliminate al the resonance that bare aluminium has.

The final result is pretty satisfying to me, I enjoy searching practical solutions using spare and leftover materials and checking what comes out.

It is pretty solid and sturdy, the light glows gently from the hole with a sort of depth sensation and the Tone Board sounds simply fantastic (this is not my merit althoigh).

An enormous thank to TimW for his fantastic tutorial and dimes. and sorry to everybody for my bad english and TL;DR

I got a slightly oversized box cause it was only 7€ from ebay and wanted to see what I could get keeping all costs at the bare minumum.

I don't have a press drill and I'm not much experienced working metal with freehand drill, so the holes wer not really perfect but the plastic lockers of the tone board masked all the imperfections very well. As for the usb hole, it was really messed up at the beginning but I refined it wit my dremel and made it about elliptical. since it turned out a bit large i decided to seal it at the back with electrical tape that and just sliced it in the middle so that the usb port juste pushed itself through it keeping it as some kind of "glove", this ensured me against casual contact with the metal case:

I didn't want a too much flashy led on the front and preferred to make use of the integrated led of the Tone Board, creating a small aperture on the front letting it pass through it. I used colored flashlight filter (5€ from amazon for 20 pieces) to close the hole, it helps diffusing the light and can be changed in seconds if you want another color. At the moment i used the green\blue:

But since the led is slightly far from the front panel I made a sort of "tunnel" with a spare plastic corrugated pipe finely fitted, just to bring the light more directly to the hole:

It gave it a misteryous look so I can now trick fanatic audiophiles telling them this is the "black magic esoteric duct of good sound"

Finally, I placed on the bottom a leftover metal plate (covered with carbon-style vinyl just for fancy) to add some weight to the body and stuck a leftover rubber mat place on the upper part of the body to eliminate al the resonance that bare aluminium has.

The final result is pretty satisfying to me, I enjoy searching practical solutions using spare and leftover materials and checking what comes out.

It is pretty solid and sturdy, the light glows gently from the hole with a sort of depth sensation and the Tone Board sounds simply fantastic (this is not my merit althoigh).

An enormous thank to TimW for his fantastic tutorial and dimes. and sorry to everybody for my bad english and TL;DR

Last edited:

Glad reading your suggestion since It's just what I had in mind for the next "upgrade".You could line some aluminium foil on the inside of the tube to maximise the transmitted light.

[UPDATE]

OK, I've done it, and it's perfect! Just the final touch it needed, now the light appears just a bit more intense but clearly more visible from all angles and in illuminated room. Very satisfied.

Last edited:

are you talking about this case https://www.audiophonics.fr/en/alum...minum-case-for-khadas-tone-board-p-13626.htmlSeems that KTB aluminum case back in stock at audiophonics.fr so I placed my order.

I thought that why would I mess with PLA materials since there is solid aluminum at the same price approximately.

Right now my KTB is in original khadas paper box

somebodyelse

Major Contributor

- Joined

- Dec 5, 2018

- Messages

- 3,754

- Likes

- 3,053

That would be in this thread.Maybe there is some way to 3d print such a box in plastic ?

Just checked prices for 3D printing in my Country (Poland) and it is ~25 Euro - the same price than aluminium box from audiophonics.frThat would be in this thread.

Similar threads

- Replies

- 29

- Views

- 2K

- Replies

- 209

- Views

- 22K