Bought these tectonic drivers from Parts express & was wondering if there are services out there that make custom trim rings for these or Baffles?

i want to flush mount these into pods, but I would like them flush in a trim ring.

So I was wondering if any of you know anyone that does that as a service that takes the Driver measurements from the Spec sheet of the manufacturer, and creates a custom trim ring or baffle for you?

I have not has any luck just looking for one. And I think I would have to contact some CNC place to get it done.

How do the rest of you flush mount drivers for your builds? Do you just get a CNC machine? I'm about to spend money on a 3D printer if that's the way to go. What would you do? It would be my first time working with drivers that I custom flush mount.

I plan to use them in some speaker pods without grills, so that's why I wanted them to look nice.

Do you have any suggestions? I guess I could use Bondo and wood filler. But again. I never flush mounted before.

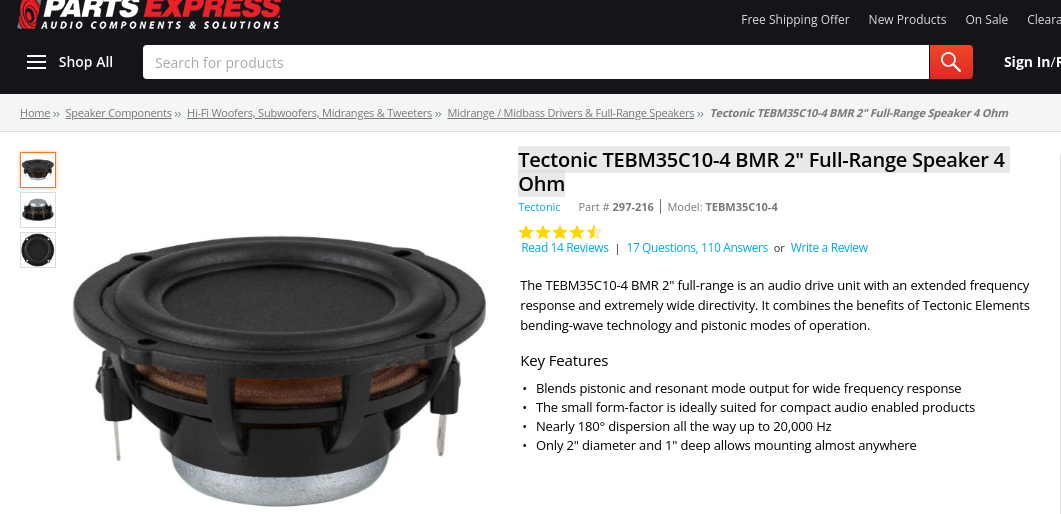

Model is the :

I really don't NEED to do it. I just wanted to do it to give the install a nice look that would look nice and almost OEM.

Later, I plan to build some Mini speakers for fun. So I was wondering what you Pro's do?

i want to flush mount these into pods, but I would like them flush in a trim ring.

So I was wondering if any of you know anyone that does that as a service that takes the Driver measurements from the Spec sheet of the manufacturer, and creates a custom trim ring or baffle for you?

I have not has any luck just looking for one. And I think I would have to contact some CNC place to get it done.

How do the rest of you flush mount drivers for your builds? Do you just get a CNC machine? I'm about to spend money on a 3D printer if that's the way to go. What would you do? It would be my first time working with drivers that I custom flush mount.

I plan to use them in some speaker pods without grills, so that's why I wanted them to look nice.

Do you have any suggestions? I guess I could use Bondo and wood filler. But again. I never flush mounted before.

Model is the :

Tectonic TEBM35C10-4 BMR 2" Full-Range Speaker 4 Ohm

I really don't NEED to do it. I just wanted to do it to give the install a nice look that would look nice and almost OEM.

Later, I plan to build some Mini speakers for fun. So I was wondering what you Pro's do?