JP

Major Contributor

OMG!

Calibrating the pickup would last longer than the record playing time...

For THAT record.

OMG!

Calibrating the pickup would last longer than the record playing time...

indeed.. as we all listen more with our brain than our ears... invite you to make small signs indicating, on the front of your devices, their sinad at 1k and snr ... (see backlit for if in the dark etc)Even when they are made with great care and at great expense, the results are troubling. This video of a boutique fabricator at work is horrifying to me. Look at how they bend, peel, and center the records by eye. Certainly vinyl shows how much you can f-up a recording and still get a pleasurable result. And that's only because human hearing is pretty limited--not to mention that most enthusiasts are aged--and people don't usually listen to it on good headphones! Poor listening room conditions help too.

The cutter typically has a 30dB feedback loop around it so this is highly unlikely.could it be a cutter heard resonance or something else?

If a synchronous motor, its locked to the line frequency which does vary although slowly. If servo controlled it too can vary. The belt stretches and releases as with torque requirements and correction. As the belt degrades, you can get buildup on the motor spindle and in the bearings of the motor shaft.Very god wow&flutter on my Gyro SE, but I do get some drift over longer time, I wonder what is causing it?

There may also be temperature related variation, as belt material may change marginally over time as the temperature of the room varies...If a synchronous motor, its locked to the line frequency which does vary although slowly. If servo controlled it too can vary. The belt stretches and releases as with torque requirements and correction. As the belt degrades, you can get buildup on the motor spindle and in the bearings of the motor shaft.

If you really want spot on speed, direct drive really is the only way to go.

Have you tried a Sutherland Timeline? You put it on the 'table and it projects dots on the wall. If they drift, its off speed. A Technics SP10 MkIII can keep the dots in the same place all day long while playing LPs with multiple needle drops. So can the SL1200G.

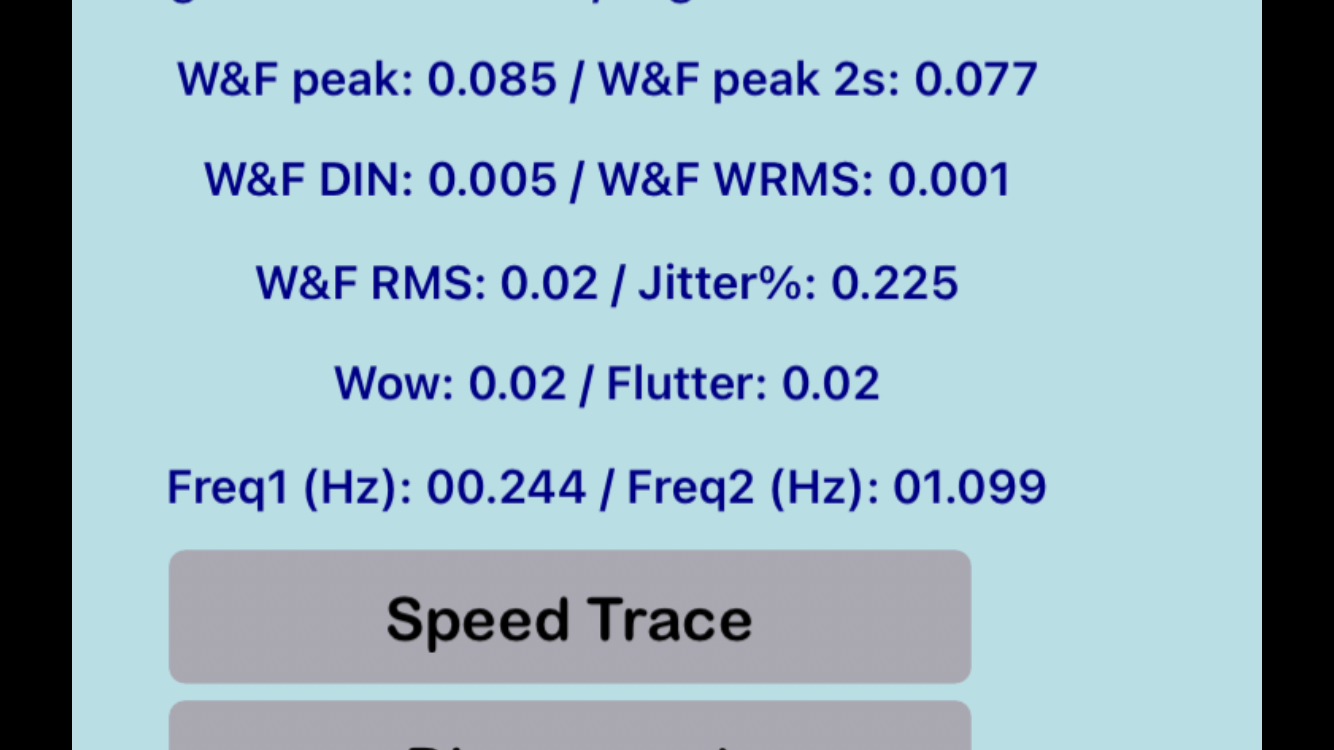

Well over the last week my DC belt driven Gyro has varied day by day by 0.02 rpm or 0.06%. But once in a while it jumps 0.5% from one day to another. I then adjust the speed by the DC PSU. But i also do get short deviations like shown in my plot . I use ShaknSpin a great tool.If a synchronous motor, its locked to the line frequency which does vary although slowly. If servo controlled it too can vary. The belt stretches and releases as with torque requirements and correction. As the belt degrades, you can get buildup on the motor spindle and in the bearings of the motor shaft.

If you really want spot on speed, direct drive really is the only way to go.

Have you tried a Sutherland Timeline? You put it on the 'table and it projects dots on the wall. If they drift, its off speed. A Technics SP10 MkIII can keep the dots in the same place all day long while playing LPs with multiple needle drops. So can the SL1200G.

Well over the last week my DC belt driven Gyro has varied day by day by 0.02 rpm or 0.06%. But once in a while it jumps 0.5% from one day to another. I then adjust the speed by the DC PSU. But i also do get short deviations like shown in my plot . I use ShaknSpin a great tool.

I guess I have to live with it , no space for a 1200 beside my Gyro and the Gyro stays for emotional reasons, and it is not so bad after all.

View attachment 263766

I am not sure I understand What you say here , but I personally find the 2S value most revealing.The only problem is that the noise in Shakenspin data is quite high , that is why I use a 10hz filter In my plot, post #345. DIN and WRMS are to flattering.. They suppress low frequency wow too much I think.why not systematize in your exchanges the recent and "hard" 2sigma aes standard?

(even if the figures are less rewarding, the standard seems to be "relevant")

You are maybe down to the test record quality limit here I think, A Shaknspin test on a SP-10R would be very interestingBe careful the chasing of one's tail:

This a set I did awhile ago comparing torque settings on an SP-10R, due to a measurement that didn't make sense but couldn't possibly be wrong 'because a magazine said so'.

Of note, these were done in my basement with a 200lb maple top table with heavy duty industrial legs. The table is in the corner of the foundation, so three legs rest on foundation footers and only one on the slab. Obvious things like turning off the heating system were done to prevent as much vibration as possible. Every step was sequenced and timed to be as consistent as I reasonably could. I threw out one entire set and red-did them because the UPS truck drove by. Of course I indexed the record so the measurement signal was the 'same' each time.

Here are two sets of W&F measurements that were repeated five times in a row. Granted these have a lot more variability having been done with a cartridge and arm.

View attachment 263814

You are maybe down to the test record quality limit here I think, A Shaknspin test on a SP-10R would be very interesting

I am much too stuck by the language to participate in your discussions etc.I am not sure I understand What you say here , but I personally find the 2S value most revealing.The only problem is that the noise in Shakenspin data is quite high , that is why I use a 10hz filter In my plot, post #345. DIN and WRMS are to flattering.. They suppress low frequency wow too much I think.

Temperature is more likely to affect the motor if is lubrication isn't up to snuff. Unless the belt is degraded, the temperature has to vary quite a lot to affect it. If the belt has stretched, the motor can't transfer its torque properly. If the belt is too thick, in some cases the platter will run too fast (this is a classic problem with the old Empire turntables, if you get the commonly offered belt from Russell Industries, which is the same belt that was made by Projector Recorder Belt Company, who Russell Ind. bought out; they never fixed that bug).There may also be temperature related variation, as belt material may change marginally over time as the temperature of the room varies...

I don't mean to offend, but why on earth would someone spend $1200 on a bearing "upgrade" for an old turntable? If the difference between a turntable with a functional bearing and your old one is audible, then the problem was with your old turntable and bearing, in which case you are better off either fixing it or even replacing it with a cheap modern turntable.I have a LP12 that ive upgraded and serviced myself over the years.

Ive been thinking about testing various upgrades and changes and reporting the results.

First up might be a Karousel bearing.

What would be the most relevant measurements to show if Linn's latest pixie dust is doing anything or not?