-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CSS Audio Criton 1TD-X Build Log

- Thread starter mtmpenn

- Start date

- Thread Starter

- #22

Yup, small router with a flush trim bit, followed by some light sanding. I also have a veneer saw, which I am using to cut the pieces to rough size before the glue up. That would work to trim after gluing too, but the router is a little easier.

- Thread Starter

- #23

These are basically the tools - nothing special:

And here is an example of the veneer and cabinet with a thin coat of glue. I have been ironing just after the glue is dry to the touch.

There have been a few small bubbles, but I think that I have been able to flatten them by hitting it with the iron again and increasing the pressure. I guess I will know for sure once I start to finish.

And here is an example of the veneer and cabinet with a thin coat of glue. I have been ironing just after the glue is dry to the touch.

There have been a few small bubbles, but I think that I have been able to flatten them by hitting it with the iron again and increasing the pressure. I guess I will know for sure once I start to finish.

Last edited:

- Thread Starter

- #27

Success!! Driver cutouts have been trimmed without any disasters.

The veneer is brittle and I was very worried about cracking/tearing/ripping. As seen in the prior image, I used a razor blade to make pilot holes in the veneer before gluing. I then used a “small pilot flush trim” bit in my router:

And the end result:

Next stop, sanding and finishing…

The veneer is brittle and I was very worried about cracking/tearing/ripping. As seen in the prior image, I used a razor blade to make pilot holes in the veneer before gluing. I then used a “small pilot flush trim” bit in my router:

And the end result:

Next stop, sanding and finishing…

Those look fantastic!

Do you use regular wood glue for the iron on method?

Anyone know what to thin shellac with if you can't get denatured alcohol?

Grain alcohol works great (Everclear or something similar). Woodworkers often use that before prohibition.Those look fantastic!

Do you use regular wood glue for the iron on method?

Anyone know what to thin shellac with if you can't get denatured alcohol?

Colonel7

Addicted to Fun and Learning

They look great. That's really clever to have filled the magnets in and veneered over them. Can't tell they're there.1 coat BLO and several light wiped on coats of blonde shellac (zinsser) later:

View attachment 147204

I should be able to finish up the exterior of the cabinets tomorrow!

- Thread Starter

- #33

Those look fantastic!

Do you use regular wood glue for the iron on method?

Anyone know what to thin shellac with if you can't get denatured alcohol?

I have some info in post 20 about the approach, but yup, it is regular wood glue (Titebond II). I would have preferred HeatLock, but it was sold out.

Some caveats - I did experience minor cracking in 2 panels and I had a few small bubbles. Some adjustment in technique seemed to have solved those issues, but there was some learning curve for me.

Also, you can’t tell in the pictures but the veneer is not totally flat. This is sort of hard to describe, but it has a tightly curled figure. When you rub your fingers over the figure it is a little bit lumpy (you can feel the curls). I could not sand it out (afraid I would sand through the veneer).

It’s not a big deal for me. These will be satin when done and I think they will look good. But, I wanted to note it, as I suspect the ironing process has contributed (lots of moisture changes).

I have never worked with raw veneer before, never worked with a curly wood veneer, and never veneered in any way other than iron-on, but I suspect that things would be more flat and a bit better overall with another technique (ie vacuum press or cold press technique… maybe contact cement but that seems to have mixed reports on the internet). If there is anyone reading with more experience - feel feee to chime in!

I think you have to use alcohol to thin shellac. I actually used everclear (180 proof grain alcohol) rather than denatured alcohol, just like noted by PresbyByrd. I used about equal parts zinsser canned shellac and everclear.

- Thread Starter

- #34

So when are you coming out to Houston to veneer mine? Looking slick! Have you put the crossovers together yet?

Well, I built my last set of speakers around 2010, so it might be a while! In one of the pictures you can see the carcass of a dual passive radiator sub that has been “in process” (sitting, ignored in the basement) for about a decade.

Kerry Armes

Member

- Joined

- Aug 13, 2021

- Messages

- 5

- Likes

- 25

Hi mtmpenn,

The cabinets look great so far.

Half the reason we use the rabbeted edges is to prevent air leaks. You should not have to caulk around the inside at all, especially with the number of clamps you used.

A couple of tips for your next veneer job - the iron on method doesn't work well with raw wood. Like you found out, without the paper backer the stability is lower and it warps and cracks with the iron. You can minimize this but never prevent it completely. You don't have to have a vacuum press to do cold pressing though. You can actually just use a sheet of MDF or plywood at least a little bigger in each direction than the panel you are applying to. Put the wood glue down, then the veneer, then lay a sheet of wax paper over the veneer. Finally, place the piece of wood over the top and clamp it down. With pieces that don't have a large span in the middle where you would have little force, this can replace the vacuum press and you will get much better results. I just convinced a friend to try the same thing. He had been trying iron on with raw veneer (first time veneering in general) and getting similar results as you. After switching he called me to say he couldn't believe how much better it turned out and if he knew it could work so well and be so easy to get results like that he would have started veneering years ago.

The cabinets look great so far.

Half the reason we use the rabbeted edges is to prevent air leaks. You should not have to caulk around the inside at all, especially with the number of clamps you used.

A couple of tips for your next veneer job - the iron on method doesn't work well with raw wood. Like you found out, without the paper backer the stability is lower and it warps and cracks with the iron. You can minimize this but never prevent it completely. You don't have to have a vacuum press to do cold pressing though. You can actually just use a sheet of MDF or plywood at least a little bigger in each direction than the panel you are applying to. Put the wood glue down, then the veneer, then lay a sheet of wax paper over the veneer. Finally, place the piece of wood over the top and clamp it down. With pieces that don't have a large span in the middle where you would have little force, this can replace the vacuum press and you will get much better results. I just convinced a friend to try the same thing. He had been trying iron on with raw veneer (first time veneering in general) and getting similar results as you. After switching he called me to say he couldn't believe how much better it turned out and if he knew it could work so well and be so easy to get results like that he would have started veneering years ago.

- Thread Starter

- #36

Hi mtmpenn,

The cabinets look great so far.

Half the reason we use the rabbeted edges is to prevent air leaks. You should not have to caulk around the inside at all, especially with the number of clamps you used.

A couple of tips for your next veneer job - the iron on method doesn't work well with raw wood. Like you found out, without the paper backer the stability is lower and it warps and cracks with the iron. You can minimize this but never prevent it completely. You don't have to have a vacuum press to do cold pressing though. You can actually just use a sheet of MDF or plywood at least a little bigger in each direction than the panel you are applying to. Put the wood glue down, then the veneer, then lay a sheet of wax paper over the veneer. Finally, place the piece of wood over the top and clamp it down. With pieces that don't have a large span in the middle where you would have little force, this can replace the vacuum press and you will get much better results. I just convinced a friend to try the same thing. He had been trying iron on with raw veneer (first time veneering in general) and getting similar results as you. After switching he called me to say he couldn't believe how much better it turned out and if he knew it could work so well and be so easy to get results like that he would have started veneering years ago.

Thanks Kerry! (For others. Kerry is one of the owners of CSS and was very responsive to me when I emailed with a question about their kits about 9 months ago - took me a while to pull the trigger).

I appreciate the tip. Next time I will definitely try pressing. It seems like with your version you are not bothering with cauls - just clamps? I guess the panels are small so maybe no need? And do you use regular wood glue?

I have not heard them yet, but the kit is fantastic. Packaging/parts quality/attention to detail are all impressive!

- Thread Starter

- #37

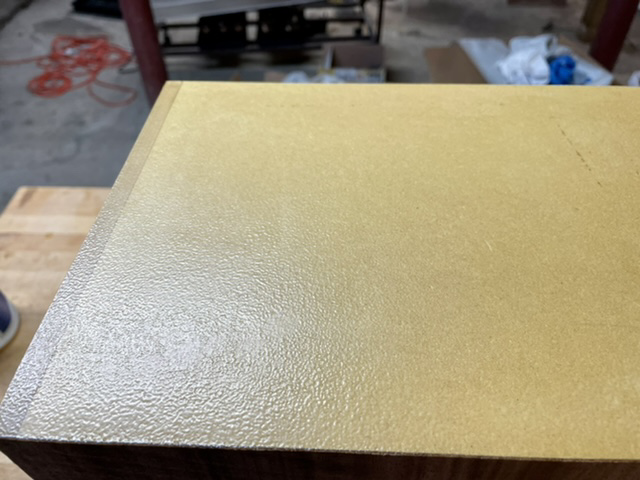

For context, this picture shows the “texture.”

It is subtle and the cabinets will still look great when done (they will be less glossy ultimately) but next time I will definitely try pressing without the iron.

On the plus side though, I think I did a very good job lining up the grain so that it looks like one veneer piece wrapping the cabinet.

It is subtle and the cabinets will still look great when done (they will be less glossy ultimately) but next time I will definitely try pressing without the iron.

On the plus side though, I think I did a very good job lining up the grain so that it looks like one veneer piece wrapping the cabinet.

ta240

Major Contributor

- Joined

- Nov 7, 2019

- Messages

- 1,427

- Likes

- 2,861

Thanks for the replies. I tried some 95% Isopropyl for the shellac that seemed to work, hopefully it won't cloud it when it dries. Denatured alcohol isn't available in California anymore.

You did great with lining the grain up on there. I did my first veneer recently but it was with pressure sensitive adhesive on it, so I cheated a bit.

You did great with lining the grain up on there. I did my first veneer recently but it was with pressure sensitive adhesive on it, so I cheated a bit.

- Thread Starter

- #39

Thanks for the replies. I tried some 95% Isopropyl for the shellac that seemed to work, hopefully it won't cloud it when it dries. Denatured alcohol isn't available in California anymore.

You did great with lining the grain up on there. I did my first veneer recently but it was with pressure sensitive adhesive on it, so I cheated a bit.

No such thing as cheating! But where are the pictures of it?

- Thread Starter

- #40

Hi mtmpenn,

The cabinets look great so far.

Hey Kerry - should I line the side walls of the upper portion of the cabinet with foam? Some of the YouTube builds just seem to do the lower portion (near the woofer).

Thanks,

Mike

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 29

- Views

- 2K

- Replies

- 77

- Views

- 7K