thefsb

Addicted to Fun and Learning

- Joined

- Nov 2, 2019

- Messages

- 796

- Likes

- 657

I need to add absorbers on a couple of walls in room where I use an LDC mic and, not simultaneously, a pair of 5" loudspeakers (Genelec 1029A).

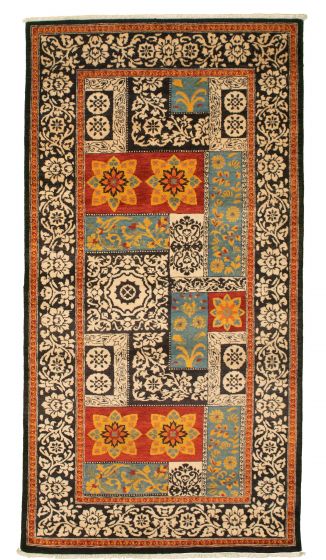

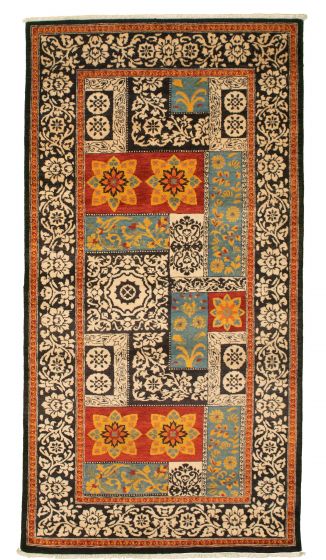

For example I could try to hide four 2' x 4' panels of 4" Ownens Corning 705 behind a decorative 4' x 8' rug like the one shown.

Do y'all have experience or advice to share on the materials, construction and mounting? For example, 2" 703 and 705 is available with facing which might simplify my work. And should I construct air gaps into the panels?

For example I could try to hide four 2' x 4' panels of 4" Ownens Corning 705 behind a decorative 4' x 8' rug like the one shown.

Do y'all have experience or advice to share on the materials, construction and mounting? For example, 2" 703 and 705 is available with facing which might simplify my work. And should I construct air gaps into the panels?