The pictures are not in any chosen order, just the one the software chose when I loaded them.

This is the base with the isolation suspension and the leveling adjusters poking out, the big knurled rings adjust the base height of the isolator.

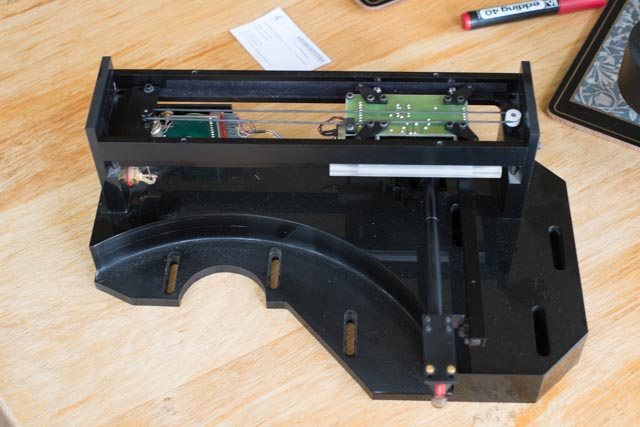

This is the cast "subchassis" with subplatter still in place and speed sensor cable. It has a cutout for mounting a pivoted arm and holes to clamp their own parallel tracker in place.

This is the motor controller which is normally suspended under the base stand.

This is the T3F parallel tracking arm the shorter arm to its side holds a sensor used by the arm controller to move the pivot to keep the arm parallel. Most parallel trackers use the cartridge to keep the arm parallel which has the side effect of a high lateral effective mass, which more than negates the benefit of parallel tracking because it still has the reduced distortion but the sum channel bass response is inaccurate (ie it is excessive so many may well like it!).

This is the bottom of the motor carrier. The 3 spikes are threaded so one can level and adjust the height of the motor pulley. It is a big block of bronze and very heavy indeed.

Top of the motor carrier showing pulley. The motor looks like a normal Philips syncronous one to me.

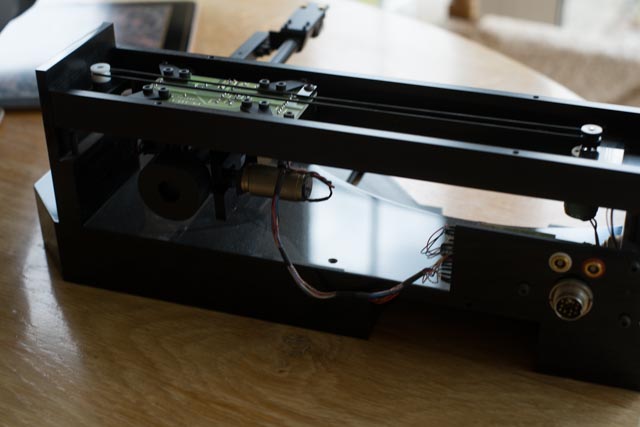

Back of the arm assembly showing the controil motor, the scarily tiny-wired harness and the Lemo cartridge connectors and the connector for the controller.

Bottom view of cast Subchassis.

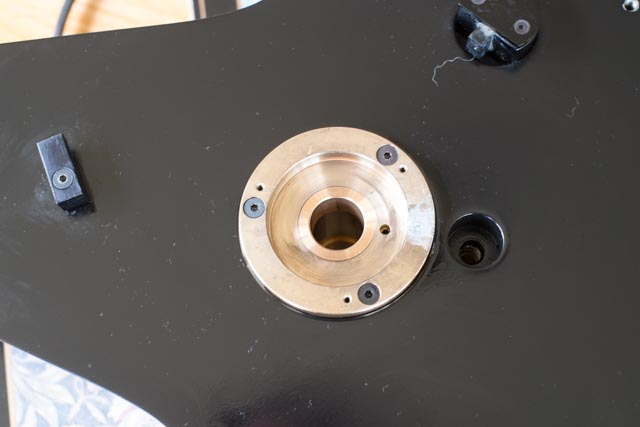

Main bearing. This was modified over the life of the design. This unit was Goldmund Europe's demonstrator so had the latest mods. the large diameter at the top forms an oil reservoir from which the small hole allows oil to circulate down to the area between the two bushings.

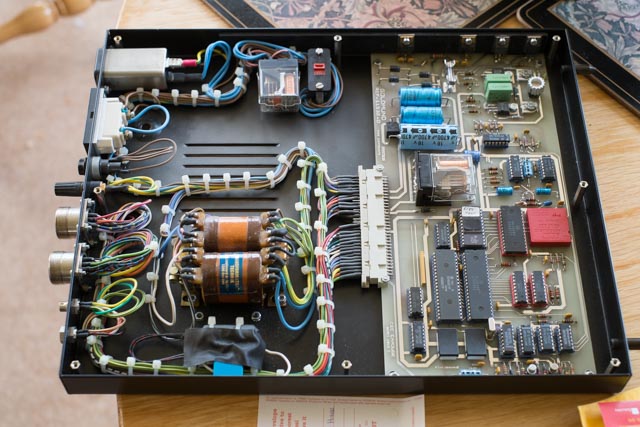

This is the inside of the motor controller box.

These are the 3 receptacles for the cones on the motor mount. They are eccentric and set into the top plate such that one can rotate them thereby moving the whole motor assembly to set belt tension.

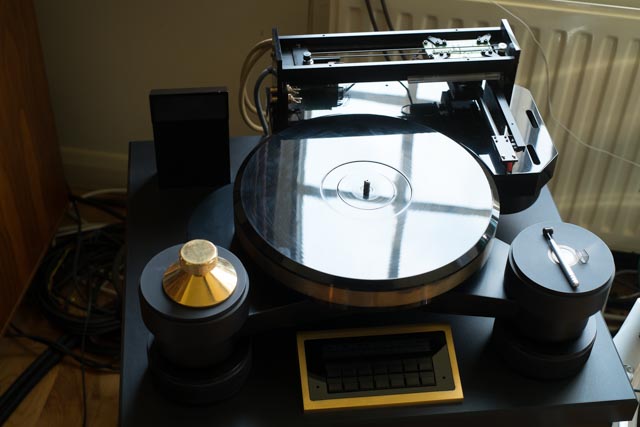

The assembled TT without the cover on the arm traverse which vibrates and affects the cartridge output, so I remove it for listening.

The subchassis is bolted to the top of the isolators and the weights which sit on each tower have a felt disc but are calibrated to tune the isolator suspension.

Turntable with platter removed. The platter is so heavy that the suspension extension almost pulls the belt off its pulley when it is removed.

Playing a record, it is obvious I am going to have to replace a bulb in the display at the next service (I didn't have a bulb when I did this one).

Platter. It is an acrylic/bronze/acrylic sandwich and very heavy. The top is very slightly conical with the centre about 1mm lower than the periphery. When the clamp is fitted this pulls slight warps to flat.

Being a bit obsessive I "level" the subchassis such that it is slightly cocked over to one side such that the bit of platter under the arm trajectory is horizontal.

This is the base with the isolation suspension and the leveling adjusters poking out, the big knurled rings adjust the base height of the isolator.

This is the cast "subchassis" with subplatter still in place and speed sensor cable. It has a cutout for mounting a pivoted arm and holes to clamp their own parallel tracker in place.

This is the motor controller which is normally suspended under the base stand.

This is the T3F parallel tracking arm the shorter arm to its side holds a sensor used by the arm controller to move the pivot to keep the arm parallel. Most parallel trackers use the cartridge to keep the arm parallel which has the side effect of a high lateral effective mass, which more than negates the benefit of parallel tracking because it still has the reduced distortion but the sum channel bass response is inaccurate (ie it is excessive so many may well like it!).

This is the bottom of the motor carrier. The 3 spikes are threaded so one can level and adjust the height of the motor pulley. It is a big block of bronze and very heavy indeed.

Top of the motor carrier showing pulley. The motor looks like a normal Philips syncronous one to me.

Back of the arm assembly showing the controil motor, the scarily tiny-wired harness and the Lemo cartridge connectors and the connector for the controller.

Bottom view of cast Subchassis.

Main bearing. This was modified over the life of the design. This unit was Goldmund Europe's demonstrator so had the latest mods. the large diameter at the top forms an oil reservoir from which the small hole allows oil to circulate down to the area between the two bushings.

This is the inside of the motor controller box.

These are the 3 receptacles for the cones on the motor mount. They are eccentric and set into the top plate such that one can rotate them thereby moving the whole motor assembly to set belt tension.

The assembled TT without the cover on the arm traverse which vibrates and affects the cartridge output, so I remove it for listening.

The subchassis is bolted to the top of the isolators and the weights which sit on each tower have a felt disc but are calibrated to tune the isolator suspension.

Turntable with platter removed. The platter is so heavy that the suspension extension almost pulls the belt off its pulley when it is removed.

Playing a record, it is obvious I am going to have to replace a bulb in the display at the next service (I didn't have a bulb when I did this one).

Platter. It is an acrylic/bronze/acrylic sandwich and very heavy. The top is very slightly conical with the centre about 1mm lower than the periphery. When the clamp is fitted this pulls slight warps to flat.

Being a bit obsessive I "level" the subchassis such that it is slightly cocked over to one side such that the bit of platter under the arm trajectory is horizontal.