Hello guys,

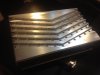

Actually I'm submitting this thread to use the wisdom of the crowd and hear the ideas about designing and building amplifiers based on Hypex/Purifi and possibly Pascal modules. For now, we are focusing on Hypex NC252MP to see how it will turn out. Afterwards we will work on nc1200 and NC502MP and NC500. It's been about seven or eight year we are OEM customer of Hypex, and we have built a dozen models based on Hypex for our domestic market but we many consider building some models for overseas markets as our currency value against USD has dropped significantly, so it will be worthwhile for a manufacturer to sell the product and receive USD and the buyer will also pay less because of lower manufacturing cost. We tend to build the chassis out of 6061-T6 aluminum alloy billet. Here are some models we have built so far, although they might not be perfect and that's why I'm looking for opinions here to revise the designs for a better product.

We usually hard-anodize aluminum after machining, and it will be anti-scratch, although it will decrease thermal conductivity a little.

We thought we may be able to build a stereo amplifier based on Hypex NC252MP with single piece aluminum body for less than 500 bucks and then try other models like nc1200 and nc500 and Purifi afterwards. This is the concept for now. It's a 200mm x 200mm x 58mm. We try to keep the appearance simple and minimalist. Modules will be mount up-side-down on the top of the chassis so whole the aluminum body will act as a big heat sink:

There will be some ventilation slots on the bottom door so the air will get through it and the hot air will exit out of another slot on the rear wall:

For now, we want to make sure that the ventilation is adequate. Any idea for a better product is much appreciated. Hopefully we can offer the product for about 500USD (NC252MP) after the final samples are manufactured. I think this would be an unbeatable price tag considering the serious machining and material we are putting in this. This is possible because of low labor wage/energy cost/tax we have here in Iran and probably this couldn't be done elsewhere (well except China).

Actually I'm submitting this thread to use the wisdom of the crowd and hear the ideas about designing and building amplifiers based on Hypex/Purifi and possibly Pascal modules. For now, we are focusing on Hypex NC252MP to see how it will turn out. Afterwards we will work on nc1200 and NC502MP and NC500. It's been about seven or eight year we are OEM customer of Hypex, and we have built a dozen models based on Hypex for our domestic market but we many consider building some models for overseas markets as our currency value against USD has dropped significantly, so it will be worthwhile for a manufacturer to sell the product and receive USD and the buyer will also pay less because of lower manufacturing cost. We tend to build the chassis out of 6061-T6 aluminum alloy billet. Here are some models we have built so far, although they might not be perfect and that's why I'm looking for opinions here to revise the designs for a better product.

We usually hard-anodize aluminum after machining, and it will be anti-scratch, although it will decrease thermal conductivity a little.

We thought we may be able to build a stereo amplifier based on Hypex NC252MP with single piece aluminum body for less than 500 bucks and then try other models like nc1200 and nc500 and Purifi afterwards. This is the concept for now. It's a 200mm x 200mm x 58mm. We try to keep the appearance simple and minimalist. Modules will be mount up-side-down on the top of the chassis so whole the aluminum body will act as a big heat sink:

There will be some ventilation slots on the bottom door so the air will get through it and the hot air will exit out of another slot on the rear wall:

For now, we want to make sure that the ventilation is adequate. Any idea for a better product is much appreciated. Hopefully we can offer the product for about 500USD (NC252MP) after the final samples are manufactured. I think this would be an unbeatable price tag considering the serious machining and material we are putting in this. This is possible because of low labor wage/energy cost/tax we have here in Iran and probably this couldn't be done elsewhere (well except China).

Last edited: