-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

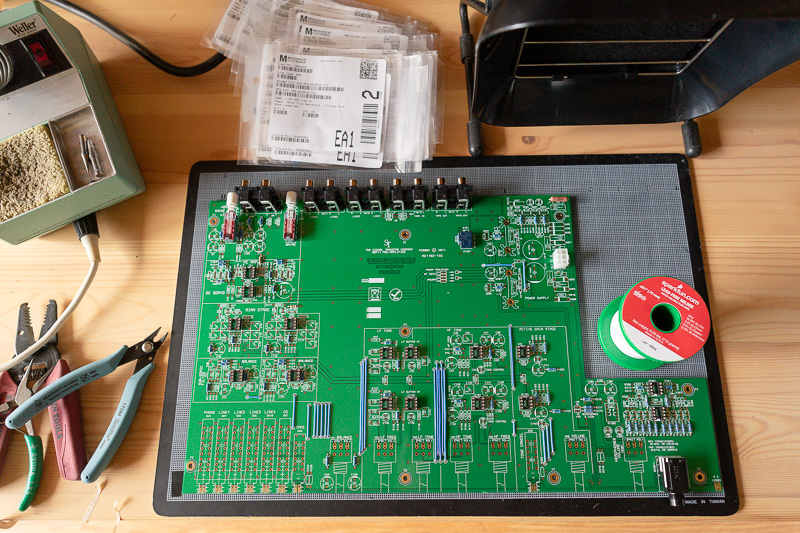

Who has any sort of electronic repair equipment/workbench and what do you have. Post pics if you like.

- Thread starter Doodski

- Start date

jhenderson0107

Active Member

Here's mine:

Last edited:

- Thread Starter

- #3

Beauty. I even recognize a few pieces of the gear that you have in your stacks of gear.Here's mine: View attachment 206138

- Thread Starter

- #4

Can you revise the method you used for the soldering station so we can see it in the thread. It's a major feature and needs to be shown as a full size pic. I used a nice stereo magnifier for some time when I worked QA/QC for a downhole tool company and it was excellent and the clarity was very good. My fav though is the lens off a old camcorder that I salvaged from the front of a lense assembly. All glass, compound assembly and could be disassembled into 5 pieces for cleaning. It really enabled various angles of viewpoint and contributed to my repairs each and every time I used it which was all the time.Here's mine: View attachment 206138

- Joined

- Jul 21, 2019

- Messages

- 2,362

- Likes

- 3,543

No permanent work space, just a small table that I use for a variety of tasks as needed. Among other tools, I have:

Ancient Weller soldering station has since been replaced with Hakko FX951 (love it)

Hakko 808 desoldering gun

Rigol DS1102 'Scope

Fluke 8060A RMS multimeter

Misc: handheld capacitance meter, capacitor ESR meter, signal generator

FLIR TG130

Monoprice Mini Delta 3D printer

No-name hot air station and hot plate.

I'm expecting to encounter fewer DIY electronics projects in the future, less through-hole construction and more SMD. For example, I have a Malahit software-defined radio in my build queue, purchased from RX9CIM long before current political mess.

Most recent projects have been film camera repairs, and there, the problems are mostly mechanical.

Ancient Weller soldering station has since been replaced with Hakko FX951 (love it)

Hakko 808 desoldering gun

Rigol DS1102 'Scope

Fluke 8060A RMS multimeter

Misc: handheld capacitance meter, capacitor ESR meter, signal generator

FLIR TG130

Monoprice Mini Delta 3D printer

No-name hot air station and hot plate.

I'm expecting to encounter fewer DIY electronics projects in the future, less through-hole construction and more SMD. For example, I have a Malahit software-defined radio in my build queue, purchased from RX9CIM long before current political mess.

Most recent projects have been film camera repairs, and there, the problems are mostly mechanical.

- Joined

- Jul 21, 2019

- Messages

- 2,362

- Likes

- 3,543

Whoa.

- Thread Starter

- #7

Yes, very impressive. I have only seen one console/repair/calibration station like this that was more comprehensive and bigger. That was a metrology lab I worked @ part time. Very nice stacks of gear.Whoa.

I'm liking the fan in the upper left of the picture. I didn't see any ventilation on the other pics!No permanent work space, just a small table that I use for a variety of tasks as needed. Among other tools, I have:

Ancient Weller soldering station has since been replaced with Hakko FX951 (love it)

Hakko 808 desoldering gun

Rigol DS1102 'Scope

Fluke 8060A RMS multimeter

Misc: handheld capacitance meter, capacitor ESR meter, signal generator

FLIR TG130

Monoprice Mini Delta 3D printer

No-name hot air station and hot plate.

I'm expecting to encounter fewer DIY electronics projects in the future, less through-hole construction and more SMD. For example, I have a Malahit software-defined radio in my build queue, purchased from RX9CIM long before current political mess.

Most recent projects have been film camera repairs, and there, the problems are mostly mechanical.

View attachment 206140

Tom C

Major Contributor

Well…

I have a soldering iron and some basic tools. That’s about it. It’s not as easy to repair most things as it was back in the day.

I have a soldering iron and some basic tools. That’s about it. It’s not as easy to repair most things as it was back in the day.

- Thread Starter

- #11

I'll second that. I'm acclimated to ordering any electronic/mechatronic parts for repair and getting them too. Not today!Well…

I have a soldering iron and some basic tools. That’s about it. It’s not as easy to repair most things as it was back in the day.

JRS

Major Contributor

That "dissecting" scope is a killer, what these old eyes would give for that. What does one of those run?

- Joined

- Jul 21, 2019

- Messages

- 2,362

- Likes

- 3,543

Especially when some manufacturers guard access to service data and parts like state secrets.I'll second that. I'm acclimated to ordering any electronic/mechatronic parts for repair and getting them too. Not today!

jhenderson0107

Active Member

Equipment ventilation: Rackmount fans are mounted into the rear of each shelf, flowing upwards. The uppermost shelf vents to outside. The solder station has no fume hood, but it's located in the shop which has great ventilation.

The fan shown on the electronics bench is actually cooling an RFSoC chip which dissipates ~45W under load. A much nicer, custom heat spreader is available but since I swap devices regularly, a desktop fan is easier to use.

The microscope is a Mantis Compact with x6 objective. They're about $1500 new, but I bought second-hand.

The fan shown on the electronics bench is actually cooling an RFSoC chip which dissipates ~45W under load. A much nicer, custom heat spreader is available but since I swap devices regularly, a desktop fan is easier to use.

The microscope is a Mantis Compact with x6 objective. They're about $1500 new, but I bought second-hand.

- Thread Starter

- #15

Is that a Tektronix portable O-scope on the right side of the pic?Equipment ventilation: Rackmount fans are mounted into the rear of each shelf, flowing upwards. The uppermost shelf vents to outside. The solder station has no fume hood, but it's located in the shop which has great ventilation.

The microscope is a Mantis Compact with x6 objective. They're about $1500 new, but I bought second-hand.

jhenderson0107

Active Member

No, that's a Fieldfox VNA. The left third of the bench is low frequency: Power supplies, DVMs, etc. The middle third is mid frequency (to 6 GHz). The right third is higher frequency (to 26 GHz). Most of the stuff I work on is < 10 GHz.Is that a Tektronix portable O-scope on the right side of the pic?

Last edited:

I got the following equipment, solely to restore, maintain and check my hifi/video gears. I do not have a well organized workbench yet. That's entirely due to my natural laziness (  ) and the scarcity of the work I have to do so far.

) and the scarcity of the work I have to do so far.

- Leader LAG-125 audio signal generator ;

- various laserdiscs, CDs, SA-CD and DVD-V or CD-V with test signals : Denon Technical Audio CD, Sony YEDS-18 test disc CD, Denon Audio Check SACD, Digital Video Essential DVD, Video Essential and Pioneer GGV1013 laserdiscs, etc...

- Leader LMV-181A AC wide-band millivoltmeter ;

- Beckman Industrial Model 9020 20 MHz analogue oscilloscope ;

- Boonton 1130 distortion analyzer ;

- Hewlett-Packard 3581A wave analyzer ;

- Rohde & Schwarz UPGR psophometer ;

- Tektronix CFC250 frequency counter ;

- some digital hand-held multi-meters ;

- dirt cheap Chinese MK328 component tester ;

- soldering iron, hot air soldering station, de-soldering vacuum iron, sound level meter, measuring microphone, variac and other tools.

- Leader LAG-125 audio signal generator ;

- various laserdiscs, CDs, SA-CD and DVD-V or CD-V with test signals : Denon Technical Audio CD, Sony YEDS-18 test disc CD, Denon Audio Check SACD, Digital Video Essential DVD, Video Essential and Pioneer GGV1013 laserdiscs, etc...

- Leader LMV-181A AC wide-band millivoltmeter ;

- Beckman Industrial Model 9020 20 MHz analogue oscilloscope ;

- Boonton 1130 distortion analyzer ;

- Hewlett-Packard 3581A wave analyzer ;

- Rohde & Schwarz UPGR psophometer ;

- Tektronix CFC250 frequency counter ;

- some digital hand-held multi-meters ;

- dirt cheap Chinese MK328 component tester ;

- soldering iron, hot air soldering station, de-soldering vacuum iron, sound level meter, measuring microphone, variac and other tools.

Last edited:

Similar threads

- Poll

- Replies

- 98

- Views

- 4K

- Replies

- 21

- Views

- 2K

- Replies

- 83

- Views

- 5K

- Replies

- 69

- Views

- 5K