Hello,

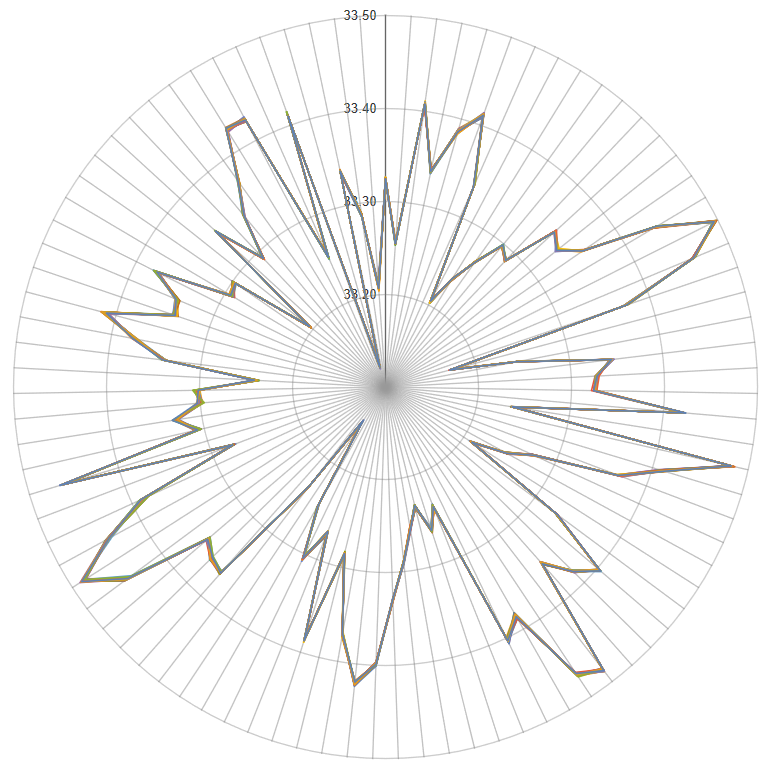

I found this forum and discussion while searching for a detailed technical manual on the Technichs SL1200mk7. I just want to add to the fun with some recent measurements on the speed stability of a SL1200mk7. Speed is measured by counting periods between optical pulses reflected from the strobe dots along the platter rim. Measurements are made using a time-interval counter in continuous (back-to-back) sampling mode with a sampling time corresponding to two periods of the strobe dot pattern. The first figure shows the angular variation of individual frequency samples, with a total of 57 revolutions overlaid. The highly reproducible pattern suggests that the measured variations are due to geometric variations of the strobe dot pattern, and not an actual variation in the platter's rotational speed. I guess this could be investigated using a high quality test record.

Since frequency measurements are continuous and synchroneous with the actual rotation of the platter, it is easy to compute a synchroneous low pass filtered rotation speed by computing the moving average over exactly one full rotation. Such averages shown below as a deviation from the nominal rotation speed of 33 1/3 rpm.

The average speed deviation is 0.001 % and the variations around this value (averaged over one full rotation) are < 0.0015 % in magnitude. A fuller view of the data are captured in the frequency stability plot shown below.

The (modified) Allan deviation indicates the typical relative difference between consecutive values of the average frequency/speed, for a given averaging interval (tau). The first 'dip' of the stability corresponds to an averaging interval of one full rotation and simply reflects what is shown in the first figure, namely that the variations in measured speed are very reproducible from one rotation to the next. For averages over more than 5 rotations (9s), the differences are less than one part per million. The data presented here do not shown any detectable speed drift at a level 10^-7.

All in all, the SL1200mk7 has excellent speed accuracy and stability. The method used to measure the speed of rotation is likely influenced by geometrical imperfections of the strobe dot pattern and is therefore not a reliable indicator of short term speed variations (flutter). The measurements nevertheless suggest an absolute upper bound of 0.2 % of short term speed variations. For measuring short term variations, it would be better to directly access the speed sensing circuitry of the SL1200mk7 and the phase deviation values of the internal quartz lock loop. Any pointers to a service/repair manual?

Added: The strobe dot pattern along the platter rim is designed for a visual indication of speed accuracy. Circular dots makes the measurement setup sensitive to slight eccentricities. It would have been better with square shaped strobe dots. The optics of the measurment setup will likely be tweaked to get reduced sample-to-sample variations.